New year, new opportunities

Despite our ongoing, intense involvement in research and development, our production line has been running at high speed. We have now manufactured hundreds of devices that are already collecting telemetry data all over the world.

What’s new?

Another year has passed, and here at Yosensi, we are showing no signs of slowing down. During this period, the highlights of our achievements have been:

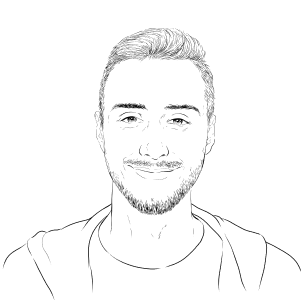

- A new device in our portfolio – YO Modbus

- New standards for device configuration – you can now set your device using simple JSON and Yosensi CLI tools instead of changing each parameter separately (Google Protocol Buffers standard implemented)

- Improvements made to existing devices - i.e., new, more distinguished reveal of the YO Pure Pro v3.0, YO Refrigerant Monitor designed with pressure sensor connected via cable

- Our devices have been successfully assessed by a notified body for compliance with the scope of the 2014/53/EU Radio Equipment Directive, according to programme PC-P-07-05

- Integration with the Helium network Yosensi Suite supports Helium network

- Undertaking a personalised project for a new customer based on LoRa technology (more information coming soon)

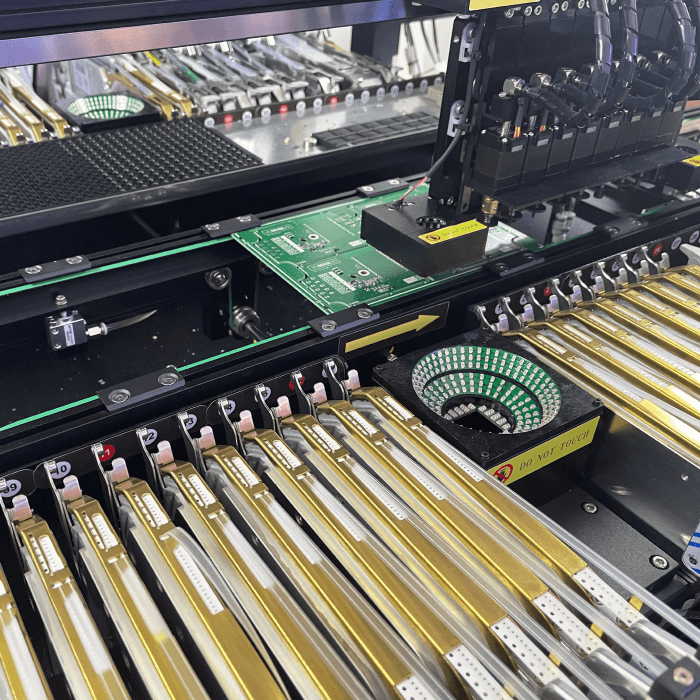

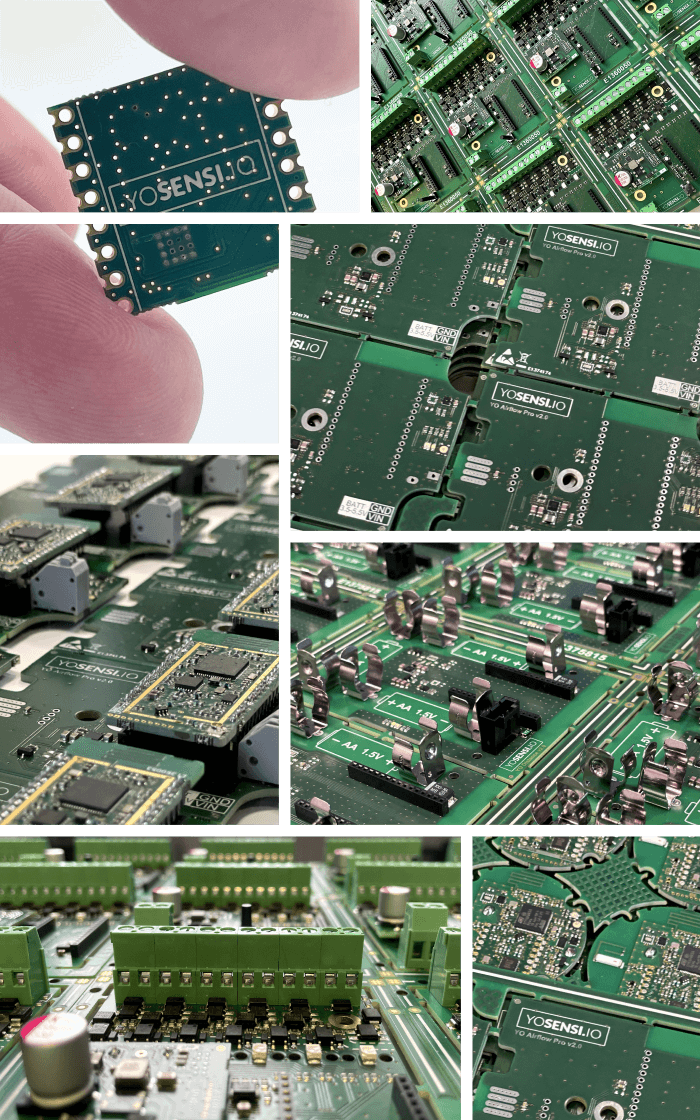

Despite our ongoing, intense involvement in research and development, our production line has been running at high speed. We have now manufactured hundreds of devices that are already collecting telemetry data all over the world.

Manufacturing at Yosensi

YO devices can now be found on almost every continent! Due to the appearance of our products in international IoT marketplaces (such as myDevices, Senet, ThingPark by Actility) and the constant interest of our current clients, since the beginning of the year, Yosensi products have found happy owners in Malaysia, Kuwait, Cyprus, Australia, the USA, the UK and Poland.

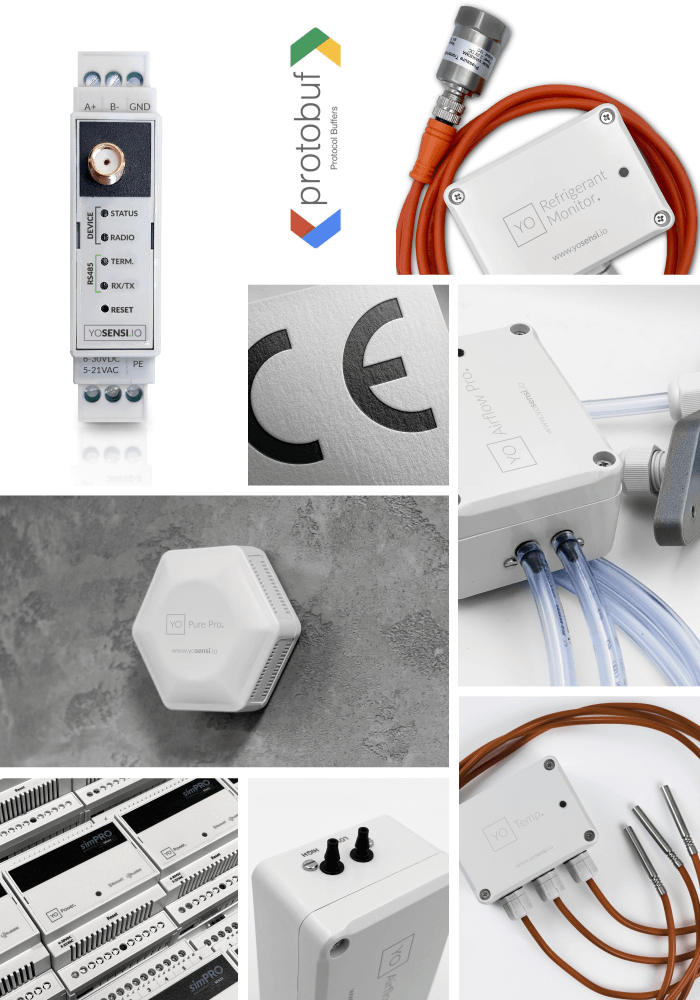

Due to the increasing popularity of our products and our constantly growing portfolio, we have upgraded our production line for manufacturing electronic devices with a high-performance Pick and Place machine. Thanks to its operation speed (up to 16,000 components per hour), 8 nozzles, 66 reel tape feeders and excellent placement precision, resulting in much more flexible, timely and economical production, we are ready to supply existing market demands and to undertake new challenges.

The new assembly unit can be quickly and easily adapted for the production of various types of devices. Additionally, due to its simplicity and convenience, we are able to improve the prototyping of new devices.

Summary

Through our new products, our current products, and significant improvements in production, we are doing our best to fulfil the expectations of our current and future clients. Our plans for the future are simple: constant development, new challenges (including personalised projects), further improvements and even more satisfied clients. Stay tuned!